Understanding Old Craftsman Air Compressor Manuals

Vintage Craftsman compressors, prized for durability, often lack readily available documentation. Fix.com and OWWM forums are invaluable resources for parts diagrams and manuals.

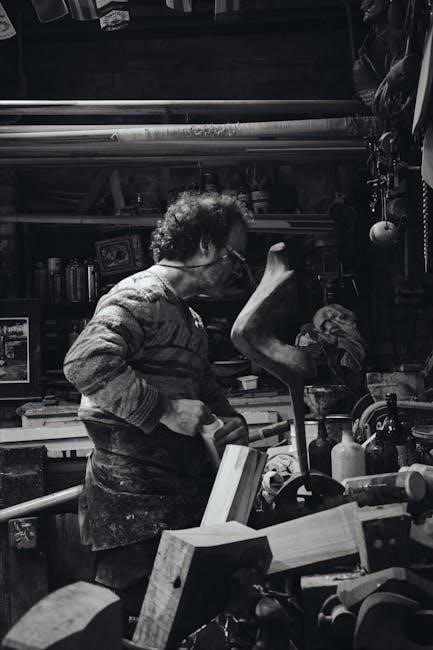

The Appeal of Vintage Craftsman Compressors

Older Craftsman air compressors hold significant appeal due to their robust build quality and longevity, often surpassing modern counterparts. Many enthusiasts report superior durability and performance compared to newer models. Stories abound of these compressors operating reliably for decades, even with demanding use. Their simpler designs facilitate easier repairs, and a strong community supports parts sourcing and troubleshooting, making them a favored choice for those seeking dependable air power.

Common Uses for Older Models

Vintage Craftsman compressors excel at typical homeowner tasks. Tire inflation and general blow-off duties are easily handled, while occasional air tool use, like impact guns or ratchets, is also feasible. These older units, particularly oil-lubricated versions, provide sufficient power for these applications, making them versatile additions to any workshop or garage setting.

Tire Inflation and General Blow-Off Tasks

Older Craftsman compressors are remarkably adept at tire inflation, quickly and efficiently filling car and bike tires. They also shine in blow-off applications, effectively clearing dust and debris from workspaces, engines, or equipment. Their consistent air delivery makes these routine maintenance tasks simple and straightforward for any user.

Occasional Use with Air Tools

While older Craftsman compressors excel at simpler tasks, they can handle air tools like impact guns or ratchets for brief periods. However, sustained use may strain the compressor, especially with higher CFM demands. Careful consideration of tool requirements and compressor limitations is crucial for optimal performance and longevity.

Identifying Craftsman Compressor Model Numbers

Craftsman compressor identification relies on deciphering the model number. Early models often began with “CH,” while newer ones frequently use “DeVilbiss” prefixes; Understanding these prefixes, alongside the numerical sequence, is key to locating specific parts diagrams and manuals, aiding in repair and maintenance efforts.

Decoding the Manufacturer’s Prefix

Craftsman compressors showcase varying prefixes indicating the original manufacturer. “CH” commonly denotes older Sears-built units, while “DeVilbiss” signifies later production. Referencing resources like OWWM’s list (http://www.owwm.com/Craftsman/Manufacturers-Prefix.asp) helps pinpoint the origin, crucial for sourcing correct parts and manuals.

Understanding Model Number Sequences

Craftsman model numbers offer clues to compressor specifications. While patterns vary, the sequence often reveals details about the unit’s design and production year. Identifying the initial numbers, as suggested by OWWM, aids in narrowing down the manufacturing period and locating compatible parts or relevant manuals for repair.

Horsepower (HP) and Cubic Feet per Minute (CFM)

Older Craftsman compressors frequently boasted higher HP ratings than modern equivalents, though CFM delivery is the crucial performance metric. Understanding the relationship between these values is vital; a higher HP doesn’t automatically guarantee superior airflow. Distinguishing between SCFM and CFM is also essential for proper tool compatibility.

The Relationship Between HP and CFM

Horsepower (HP) indicates the motor’s power, while Cubic Feet per Minute (CFM) measures actual air delivery. A higher HP can contribute to greater CFM, but efficiency and pump design are equally important. Older Craftsman units sometimes overstated HP; focus on CFM to match air tool requirements effectively.

Differences Between Older and Newer HP Ratings

HP ratings evolved; older Craftsman compressors often featured inflated figures compared to modern standards. This doesn’t necessarily mean less power, but direct comparisons are misleading. Newer ratings are more standardized and reflect actual work output. Consider CFM alongside HP when evaluating older versus newer models for performance.

Understanding SCFM vs. CFM

CFM (Cubic Feet per Minute) measures air delivery, while SCFM (Standard CFM) corrects for temperature and altitude, providing a more accurate comparison. Older Craftsman manuals frequently list SCFM, indicated by the “s”. Understanding this distinction is crucial when matching the compressor to air tool requirements for optimal performance.

Oil-Lubricated vs. Oil-Less Compressors

Oil-lubricated compressors, common in older Craftsman models, offer superior durability and quieter operation due to internal lubrication reducing friction. Oil-less compressors require less maintenance but generally have shorter lifespans and produce more noise. Choosing depends on usage frequency and desired longevity.

Advantages of Oil-Lubricated Models

Oil-lubricated Craftsman compressors, frequently found in older units, boast extended lifespans thanks to reduced wear on internal components. The oil provides cooling and sealing, resulting in quieter operation and consistent performance. They generally handle heavier, continuous use better than oil-less alternatives.

Considerations for Oil-Less Compressors

Oil-less Craftsman compressors require less maintenance, eliminating oil changes and associated mess. However, they typically have shorter lifespans due to increased friction and wear. Expect louder operation and potentially reduced performance with demanding, continuous applications compared to their oil-lubricated counterparts.

Common Issues with Older Craftsman Compressors

Older Craftsman compressors frequently exhibit motor problems, including overheating due to age and wear. Pump wear leads to reduced efficiency and lower air delivery. Expect potential issues with worn piston rings, valves, and internal seals, impacting overall performance and requiring diligent troubleshooting.

Motor Problems and Overheating

Older Craftsman compressor motors are prone to overheating, especially under heavy use, potentially tripping breakers or causing permanent damage. Worn bearings, failing capacitors, and deteriorated windings contribute to these issues. Neighbor complaints arose from voltage fluctuations impacting household lights, highlighting electrical strain.

Pump Wear and Reduced Efficiency

Older Craftsman compressor pumps experience wear and tear on pistons and cylinders, leading to reduced air delivery capacity. This manifests as slower fill times and difficulty powering air tools. Regular maintenance, like oil changes (for lubricated models), can mitigate, but not eliminate, efficiency loss over time.

Finding Replacement Parts and Manuals

Locating parts for older Craftsman compressors requires resourcefulness. Fix.com provides exploded parts diagrams, aiding identification. Online forums, particularly OWWM (Old Woodworking Machines), are invaluable communities where enthusiasts share manuals and parts sourcing information, often crucial for these vintage units;

Fix.com as a Resource for Parts Diagrams

Fix.com stands out as a premier online resource for Craftsman compressor owners seeking replacement parts. The site hosts detailed, exploded parts diagrams, allowing users to precisely identify components needed for repairs. These diagrams are model-specific, streamlining the process of finding the correct parts.

Online Forums and Communities (OWWM)

Online forums, particularly OWWM (Old Woodworking Machines), provide a vibrant community for Craftsman compressor enthusiasts. Members share manuals, troubleshooting advice, and historical context. The OWWM site specifically catalogs manufacturer prefixes, aiding in model number identification, crucial for locating relevant documentation and support.

Specific Model Examples & Historical Context

Early single-cylinder models from the 1960s, like a 1.5 HP 120V unit, were common but prone to causing electrical disturbances. Later, 4-cylinder models in the 1980s offered improved performance. Understanding this evolution helps contextualize manuals and parts availability for specific Craftsman compressors.

Early Single-Cylinder Models (1960s)

These Craftsman compressors, often around 1.5 HP and 120V, were basic but popular. However, their design sometimes caused voltage fluctuations, impacting household lights—leading to complaints and returns to Sears. Manuals for these models are scarce, emphasizing the need for resourceful parts identification.

Later 4-Cylinder Models (1980s)

Craftsman’s 1980s 4-cylinder models, frequently oil-lubricated and ranging from 3 to 5 HP, offered improved performance. Finding original manuals can be challenging; Fix.com provides exploded views for parts identification. These units generally proved more reliable than earlier single-cylinder versions, enhancing their longevity.

Electrical Considerations for Older Compressors

Older Craftsman compressors commonly came in 110V and 220V configurations. Ensure proper voltage matching and grounding for safety. Inspect wiring for damage, as insulation degrades with age. Be cautious of potential electrical issues; a flickering transformer suggests a heavy load or wiring problem, requiring professional attention.

110V vs. 220V Operation

110V models are convenient but deliver slower air recovery due to lower amperage. 220V compressors, conversely, offer significantly faster recovery and sustained performance, ideal for demanding tasks. Confirm your home’s electrical capacity before using a 220V unit, and always use the correct plug adapter for safe operation.

Potential Electrical Issues and Safety

Older compressors may exhibit frayed wiring or deteriorated insulation, posing shock hazards. Proper grounding is crucial; never remove the grounding pin. Inspect cords regularly for damage and replace if necessary. Disconnect power before any maintenance. A qualified electrician should address complex electrical repairs for utmost safety.

Troubleshooting Common Problems

Low pressure can stem from leaks in fittings or a failing check valve. Compressor cycling issues might indicate a pressure switch malfunction or insufficient airflow. Verify the belt tension and inspect for worn piston rings. Overheating suggests motor problems; allow cooling before restarting and check oil levels.

Low Pressure Issues

Low pressure frequently arises from air leaks around fittings, hoses, or the tank itself – use soapy water to detect them. A faulty check valve preventing air retention is another common cause. Inspect the compressor head gasket for deterioration, and ensure the pressure switch functions correctly.

Compressor Cycling Problems

Erratic cycling can stem from a failing pressure switch, unable to accurately sense tank pressure. A leaking check valve allows pressure to bleed off, triggering frequent restarts. Overheating, due to inadequate ventilation or motor issues, also causes cycling. Inspect the unloader valve for proper operation and sealing.

Maintenance Tips for Extending Compressor Life

Regular oil changes are crucial for oil-lubricated models, preventing sludge buildup and wear. Clean or replace the air filter frequently to ensure efficient airflow and prevent contamination. Inspect hoses and fittings for leaks, and address them promptly. Proper storage in a dry environment extends lifespan.

Regular Oil Changes (for oil-lubricated models)

Oil-lubricated compressors require periodic oil changes – typically every 3-6 months with regular use – to maintain optimal performance. Old oil becomes contaminated and loses lubricating properties, leading to increased wear. Use the manufacturer’s recommended oil type and quantity, checking levels regularly.

Air Filter Cleaning and Replacement

Air filters protect the compressor from debris, ensuring clean air intake. Regularly inspect and clean the filter – foam filters can be washed, while paper filters should be replaced. A clogged filter restricts airflow, reducing efficiency and potentially damaging the pump. Replace filters every few months, or more often in dusty environments.

Understanding Compressor Pump Components

Older Craftsman compressors utilize a piston and cylinder assembly to compress air. Check valves are crucial, ensuring one-way airflow into the tank. Worn piston rings or damaged valves lead to reduced pressure and efficiency. Understanding these components aids troubleshooting and repair, extending the compressor’s lifespan.

Piston and Cylinder Assembly

The piston, driven by the crankshaft, moves within the cylinder, compressing air during the upward stroke. Piston rings create a seal, vital for maintaining pressure. Wear on these rings diminishes compression, requiring replacement. Cylinder scoring also impacts performance, potentially necessitating a complete pump overhaul.

Check Valve Functionality

Check valves are crucial, permitting airflow from the pump to the tank, but preventing backflow. A faulty check valve leads to slow tank filling or air leaking back into the pump. Regular inspection and cleaning, or replacement if damaged, are essential for efficient compressor operation and maintaining consistent air pressure.

Resources for Manual Downloads

Sears PartsDirect remains a primary source for Craftsman manuals, utilizing the model number for targeted searches. Beyond that, numerous third-party manual archives host scanned copies of older documentation. Online forums, like OWWM, often have shared links and user-uploaded manuals, proving invaluable for locating obscure models.

Sears PartsDirect Website

Sears PartsDirect is a crucial starting point for locating Craftsman compressor manuals. Inputting the precise model number unlocks access to potentially downloadable owner’s manuals, parts lists, and wiring diagrams. While coverage varies with age, it’s often the most official and readily accessible resource for older units.

Third-Party Manual Archives

Beyond Sears PartsDirect, numerous online archives host scanned Craftsman compressor manuals. Websites dedicated to vintage tools and equipment frequently compile user-submitted documentation. These archives can be invaluable when official sources fall short, offering a broader range of models and years covered, though quality varies.

The Impact of Compressor Age on Performance

Older Craftsman compressors experience inevitable wear and tear on internal components like pistons and valves. This leads to decreased air delivery capacity and reduced overall efficiency. Seals degrade, causing leaks, and motor windings can weaken, impacting performance over decades of use.

Wear and Tear on Internal Components

Piston rings lose their seal with age, reducing compression. Valve seats become pitted, causing leaks and diminished airflow. Cylinder walls experience scoring, further impacting efficiency. These cumulative effects of wear and tear significantly reduce the compressor’s ability to maintain consistent pressure and deliver adequate CFM.

Decreased Air Delivery Capacity

As internal components degrade, an older Craftsman compressor’s ability to deliver its originally rated CFM diminishes. Worn piston rings and leaking valves contribute to this reduction. Consequently, tools may operate at lower pressures or cycle more frequently, impacting performance and project completion times.

Comparing Older Craftsman Compressors to Modern Alternatives

Older Craftsman compressors generally boast superior build quality and durability, utilizing heavier-duty components. However, modern compressors offer technological advancements like improved efficiency, quieter operation, and lighter designs. The choice depends on prioritizing longevity versus convenience and features.

Build Quality and Durability

Older Craftsman compressors were renowned for robust construction, employing cast iron pumps and substantial motors. This resulted in exceptional durability and a long service life, often exceeding that of contemporary models. While heavier, this build quality translated to reliable performance and resistance to wear and tear.

Technological Advancements in Modern Compressors

Modern air compressors benefit from innovations like lighter materials, improved motor efficiency, and sophisticated control systems. These advancements offer features such as variable speed operation and enhanced portability. However, some argue this focus on technology compromises the rugged simplicity and longevity found in older Craftsman units.

Safety Precautions When Using Older Compressors

Older Craftsman compressors require diligent safety checks. Proper grounding is crucial, given aged wiring. Regularly inspect the pressure relief valve for functionality – a critical safety feature. Be mindful of potential electrical issues and ensure adequate ventilation to prevent overheating during operation and prolonged use.

Proper Grounding and Electrical Safety

Due to the age of these units, proper grounding is paramount to prevent electrical shock. Inspect power cords for damage and ensure the outlet is correctly grounded. Consider the 110V vs. 220V operation; using the incorrect voltage can cause motor failure or create a fire hazard. Prioritize electrical safety always.

Pressure Relief Valve Functionality

The pressure relief valve is a critical safety component on older Craftsman compressors. Regularly test its functionality to ensure it releases excess pressure, preventing tank rupture. A malfunctioning valve poses a significant hazard. Never disable or tamper with this vital safety feature; proper operation is essential for safe use.